DFE Pharma becomes newest partner in the Medicines Manufacturing Innovation Centre to advance oral solid dosage medicines production

CPI has announced an agreement with DFE Pharma, making it the newest partner of the Medicines Manufacturing Innovation Centre collaboration. This partnership will enable the collaboration to draw upon DFE Pharma’s extensive expertise in the development of excipients for oral solid dosage medicines to help address key challenges facing the pharmaceutical industry today.

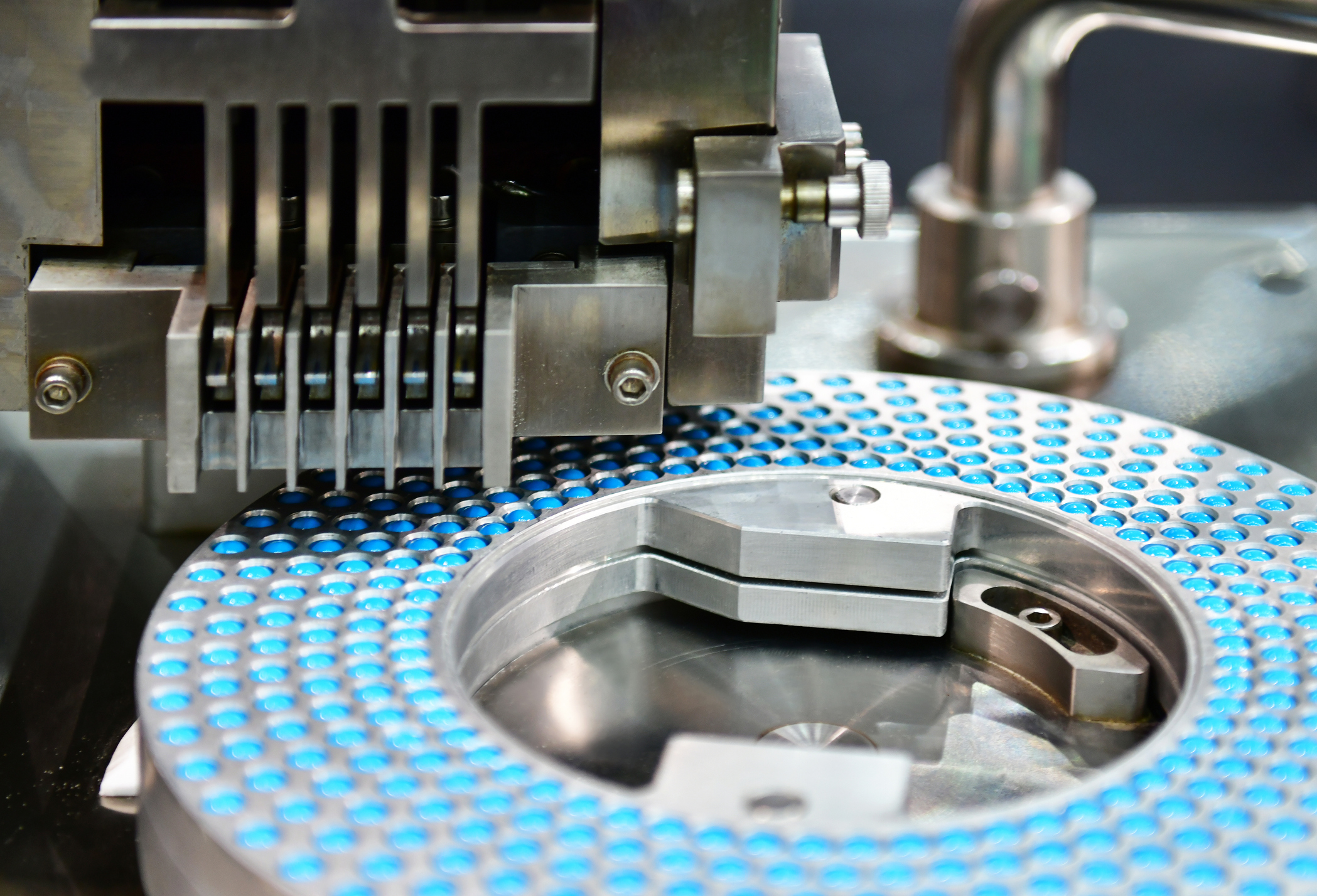

The Medicines Manufacturing Innovation Centre is a collaboration between CPI, the University of Strathclyde and founding industry partners, GSK and AstraZeneca, with funding provided by Scottish Enterprise and UK Research and Innovation. The Centre aims to advance emergent and disruptive technologies through a series of flagship ‘Grand Challenge’ projects to increase productivity and patient outcomes in the pharmaceutical industry. The new partnership with DFE Pharma will focus on Grand Challenge 1, which aims to develop a novel digitally-twinned continuous direct compression (CDC) platform to reduce waste and cut costs during the manufacture of oral dosage medicines.

DFE Pharma – a leading global excipient manufacturer – will help accelerate Phase 1 of Grand Challenge 1, as well as minimise associated costs and risks. Leveraging over 100 years of experience in developing excipients for the pharmaceutical industry, DFE Pharma will offer the Medicines Manufacturing Innovation Centre crucial expertise in excipient characterisation and functionality, quality by design, powder technology, special cause variation and commercial high-volume continuous production.

This new partnership will build on DFE Pharma’s existing contributions to Grand Challenge 1, which includes the supply of direct compression excipients that have been particle-engineered for the CDC platform. As a partner to the Medicines Manufacturing Innovation Centre, DFE Pharma will provide excipient characterisation techniques, consulting from its senior specialists, and data insights. This could significantly reduce the number of trials needed to develop the CDC platform and potentially prove invaluable in the progression of Phase 2 and future Grand Challenges to advance the development of next-generation pharmaceutical manufacturing processes.

John Arthur, Director of Medicines Manufacturing Innovation Centre at CPI, said:

“We are excited to be collaborating with global excipient manufacturer DFE Pharma; well-respected in the market for its excellence in particle technology and particle and process interactions.

“This partnership will enable Phase 1 of Grand Challenge 1 to be delivered more quickly and cost-effectively.”

Bas van Driel, CEO at DFE Pharma, said:

“We are delighted to establish a closer relationship with the Medicines Manufacturing Innovation Centre, the UK’s leading initiative to drive innovation in pharmaceutical manufacturing, to help ensure the success of Grand Challenge 1. This unique opportunity will allow us to work alongside and showcase our world-class capabilities in excipient development to the other partners.”

About the Medicines Manufacturing Innovation Centre

The Medicines Manufacturing Innovation Centre was established by a collaboration between CPI, the University of Strathclyde, UK Research and Innovation, Scottish Enterprise and founding industry partners AstraZeneca and GSK.

The consortium aims to develop the medicines manufacturing processes of the future, enabling a more agile, responsive medicines supply chain through improved manufacturing processes. It will enable new and disruptive technologies to be proven at scale in a GMP environment. This will allow the rapid adoption of next-generation processes that reduce risk, cut costs and save time, enabling a healthier society and a robust UK economy.

With a collaborative innovation culture and state-of-the-art facilities, the Centre will enable industry, academia, healthcare providers and regulators to work collaboratively in order to address challenges and maximise technology opportunities within the medicines supply chain.

The Centre is already delivering two’ ‘Grand Challenges’. The first is exploring how oral solid dosage medicines can be produced more robustly and efficiently utilising continuous direct compression. The second focuses on how these medicines can then be delivered to patients with minimal waste and maximum speed, using Just in Time manufacture and release capabilities.

By CPI - Centre for Process Innovation

598 Views

Recent Posts

- Heliex Power Saves Formaldehyde Producers £500k

- NEPIC spoke with member, Alpek Polyester UK Ltd to learn how they develop their workforce for the future and discover more about their mission to educate on PET

- FEG Global Designs Self-Powering Facility In Ghana

- Thorne & Derrick Electrifying Industry With 3M

- UK MP and chemical engineer Chris McDonald keen to unite the worlds of engineering and politics

Back to News >